BETSA® Motorized Electric Discharge Machine

EDM [MH20M]

The Motorized EDM [MH20M] has been designed to drill the tiny holes in any conductive gasket material required by the operation of Diamond Anvil Cells (DACs).

This EDM is designed and assembled in the BETSA® workshops.

Simple, efficient, robust and guaranteed to operate for 30 years

Fast drilling, high hole shape quality, high accuracy in centering and very easy operation make the [MH20M] the best tool to prepare the gaskets used in high pressure physics.

Features

• Drilling diameter : from 20µm to 500µm.

• Centring accuracy : < 5µm.

• Drills in any conducting material : Stainless steel, rhenium...

• Easy to operate

• Fast drilling : dia. 40µm /minute for a dia. 200µm hole in a stainless

steel gasket

• Possibility to change the polarisation and to tune both the

voltage and the current : to optimise drilling performances as a

function of gasket material, thickness and hole diameter.

• Centering microscope (x 400) (x200)

• Observation microscope (x 50) (x100)

• Motorized drilling : the voltage between the electrode and the

gasket feeds back to control the movement of the vertical table.

• Weight : 12 kg; Size : 19 cm wide., 33 cm deep., 42 cm high.

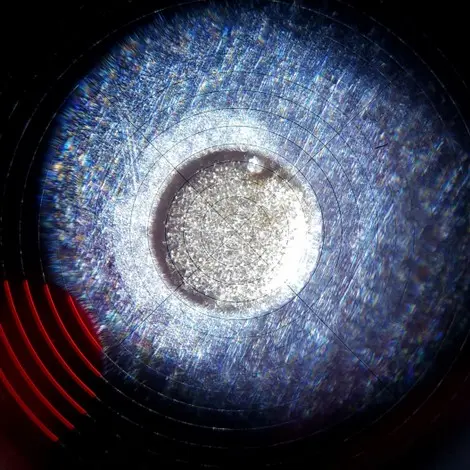

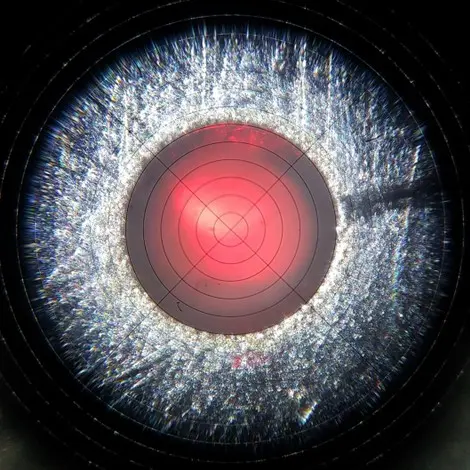

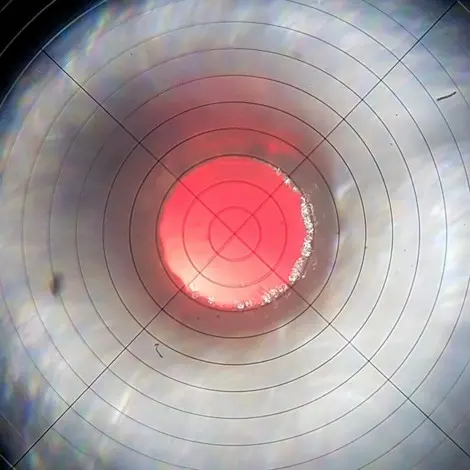

Visualisation during the drilling

Simple and effective conventional system with quality objectives

No need computer or camera software have be update.

Rotating head rotates 90 °

to change from centering visualisation position to drilling

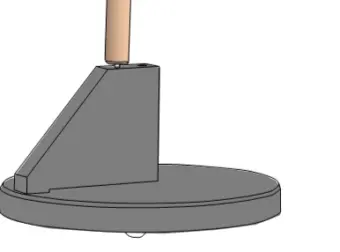

Abrasive tool for electrode used

in MH20M spark eroder

Why does BETSA® offer a sanding tool?

Because the electrodes wear out during drilling,

Their deformation over time makes conical holes.

Our electrodes very easily repositionable can be sanded with this tool to improve the electrical contact plane and the shape of the cylindrical hole, easy no!

Electrode set:

- The tungsten top of the electrode is guided in a Ø500µm hole.

Top of the needle:

- The electrode is always perpendicular to emery cloth.

Erosion of electrode:

- About 10 to 20 seconds to repair an electrode.

The abrasive tools have been designed to facilitate the repair (with emery cloth) of used and worn MH20M electrodes. The quality of the repair does not depend on the dexterity of the user. There is no risk of destroying (folding or folding) the tungsten part of the electrode.

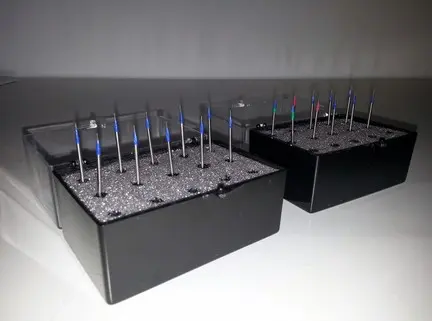

ELECTRODES

Using different diameter wires the hole diameter can be continuously varied from 60μm to 530μm by controlling the electrode voltage.

A needle is used for drilling from 10μm to 50μm.

List of Type II electrodes :

Electrode Needle radius 2µm.

Electrode Ø 50µm - 80µm - 100µm - 125µm -

150µm - 200µm - 250µm - 300µm - 380µm - 500µm